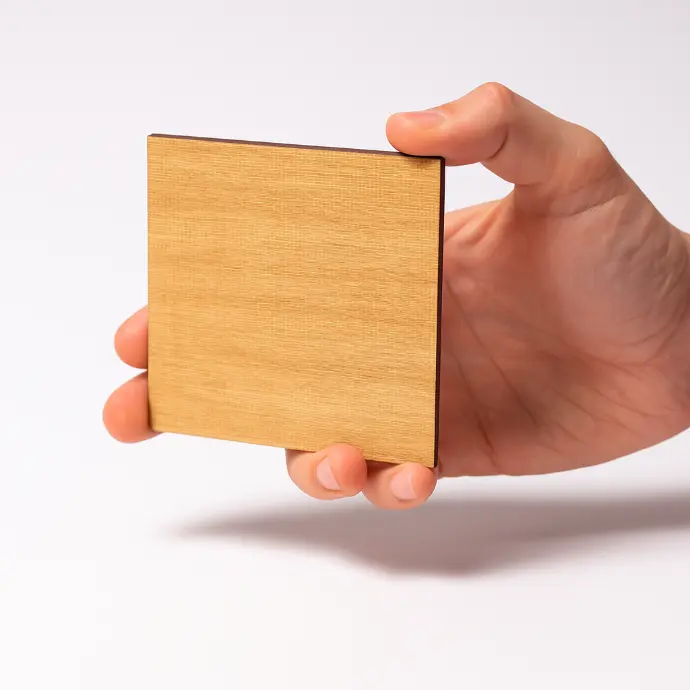

HiWood PA Prepreg Wood Fiber Paper (UD)

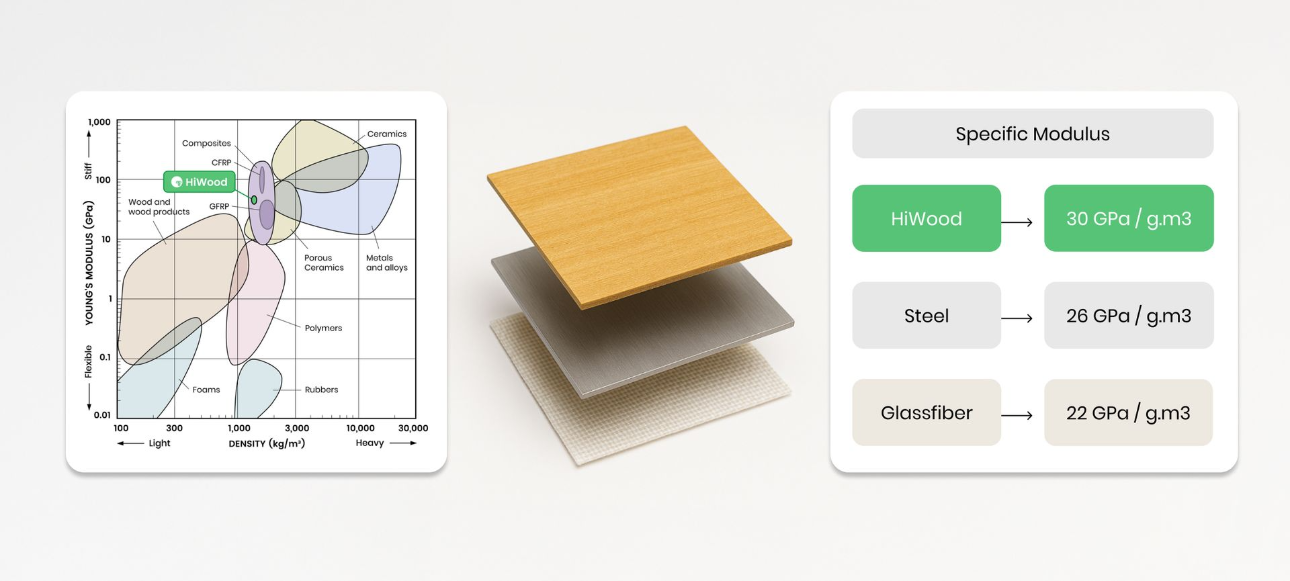

HiWood PA Prepreg Fiber Paper (UD) is a continuous wood fiber reinforcement pre-impregnated with a polyamide-based thermoplastic. It is primarily used to create continuous wood fiber-reinforced composite structures through thermoforming or stamping, eliminating the need for additional impregnation. The polar groups in polyamide chemistry enable strong interfacial bonding with wood fibers, ensuring effective adhesion within the composite. This PA prepreg wood fiber paper comes in two thickness options: 0.09mm (88g/cm²) and 0.13mm (145g/cm²).

Price listed below is per SQM.

Contact Us

45GPa

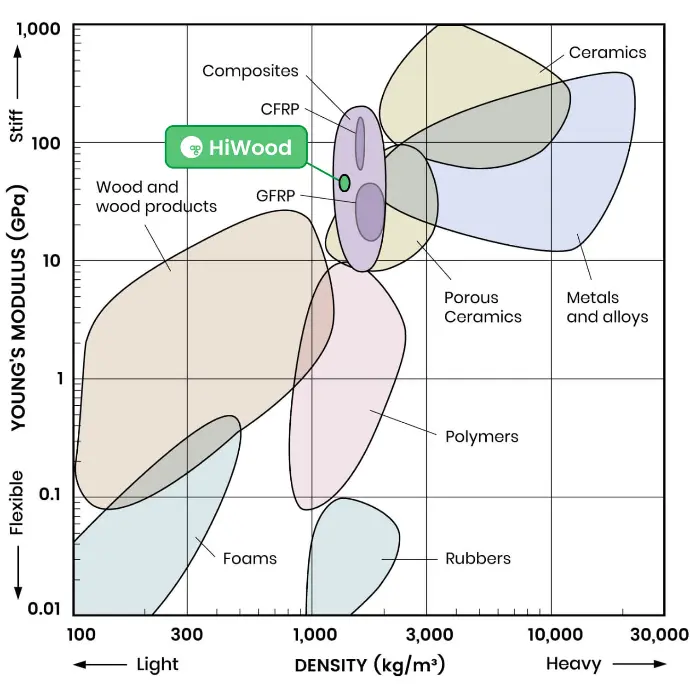

Material performance

Sustainable

bio-based, biodegradable

and recyclable

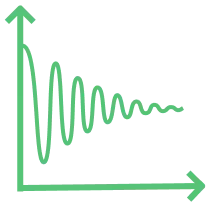

4.2% - 4.5%

Loss factor

<1.3g/cm³

Density

Engineered to Outperform.

Engineered to Outperform.

Stronger Than Flax. Still Natural.

HiWood

Reengineering wood's natural properties delivers groundbreaking stiffness and flexural strength.

+40 GPa

HiWood reinforced composite.

~20 GPa

Flax fiber reinforced composite.

Flax Fiber

Limited mechanical performance has restricted widespread adoption in high-performance applications.

The Natural Fiber Upgrade: HiWood.

HiWood

Reengineering wood's natural properties delivers groundbreaking stiffness and flexural strength.

+40 GPa

HiWood reinforced composite.

~20 GPa

Flax fiber reinforced composite.

Flax Fiber

Limited mechanical performance has restricted widespread adoption in high-performance applications.

The Natural Fiber Upgrade: HiWood.

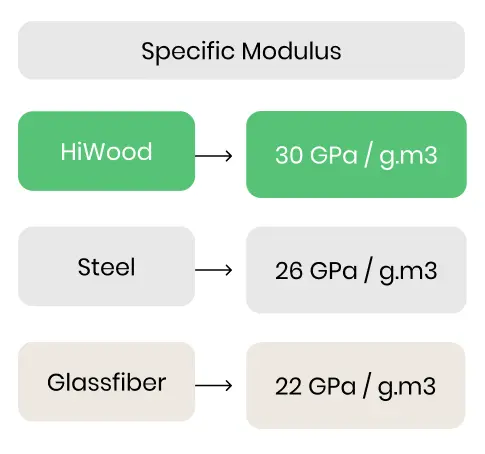

Excellent

specific strength

& modulus.

Twice the strength.

Half the weight.

Good vibrational

damping.

Naturally quiet.

Remarkably stable.

Warm wood

aesthetic.

Looks like wood.

Performs beyond.

Easy

to process.

Shape it. Cut it.

Seamlessly.

100%

Bio-based.

Fully circular.

Beautifully sustainable.

Environmentally

friendly.

Nature approved.

Performance guaranteed.

FAQ Questions

What type of resin is used in HiWood PA Prepreg?

This product uses polyamide (PA) resin, a type of thermoplastic resin. Polyamides offer good mechanical strength, wear resistance, and flexibility, particularly under dynamic loads.

Is the epoxy used in HiWood Epoxy Prepreg bio-based?

We are continuing to test bio-based epoxies to ensure a sustainable product lifecycle without sacrificing composite performance. If you'd like to learn more about our bio-based epoxies, please reach out here.

What are the processing conditions for HiWood Thermoplastic (PA) Prepreg,

Epoxy Prepreg, and Fast Cure Epoxy Prepreg - at 83 g/m²?

HiWood Thermoplastic (PA) Prepreg: 130° C

Epoxy Prepreg: 150° C, 30 min or 120° C, 60 min

Fast Cure Epoxy Prepreg: 150° C, 10 min or 130° C, 20 min

Have HiWood products been tested against other conventional

and natural composite reinforcement materials?

Of course! If there is a particular test or comparison you don't find in the product description above, let us know through our Contact Us page.

Does HiWood come in different wood tones and finishes?

Cure times and resin choice can impact the final color of HiWood reinforcement paper. However, all HiWood products are compatible with finishing paints and stains. Our team is happy to help you finetune the finish for your application

Who can I contact for technical support or inquiries?

For detailed specifications, technical support or to discuss specific applications, please reach out to the HiWood team through our Contact Us page.

More Questions? Start Here.

Whether it’s aligning specs or selecting a resin, our team

is here to help you through the details and into production.

More Questions? Start Here.

Whether it’s aligning specs or selecting a resin, our team

is here to help you through the details and into production.

SHAPED BY NATURE

AND PURPOSE.

Freshape empowers people with accessible, sustainable technologies that improve daily life. We champion autonomy, environmental care, and innovation that uplifts both individuals and the planet.